|

STANDARD MOTOR PRODUCTS QS106R

|

|

$23.79

Price

|

$0.00

Core

|

+ Sold in packs of 1x1

Pack

|

$23.79

Total

|

|

|

|

|

|

| STANDARD MOTOR PRODUCTS QS106R Specifications |

|---|

| Battery -powered | Yes | | Core Material | Nickel Coated Core | | Inflation Valve Type | Rubber | | Mounting Hardware Included | Yes | | Mounting Location | Wheel | | Mounting Method | Snap in |

|

|

| QWIK-SENSOR Multi-Frequency; 314.9, 315, and 433/434 MHz |

This sensor is blank and requires programming before installation.

- Available for both Domestic and Import applications

- Combines 314.9, 315, and 433/434 MHz applications into one

single SKU

- Factory-installed rubber valve stem interchangeable metal,

chrome, black valves available separately

- Required sensor programming can be completed before or after

installation, and while under pressure

- Surface-mounted dual band antenna ensures signal integrity and

reliability without compromising battery life to ensure data is

transmitted accurately

- Longer battery life power consumption reduced up to 30

percent

- Faster programming times

- Application Specific Integrated Circuit (ASIC) features an

accelerometer that uses multi-axis positioning which allows the

TPMS system to accurately display POD (Pressure on Demand)

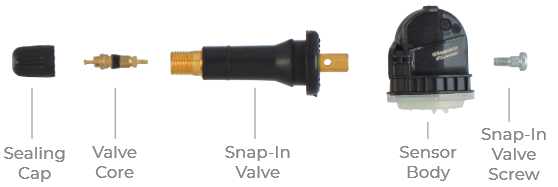

Rubber (Snap-In) Installation: A rubber-enclosed valve piece is "snapped in" to the body with a valve screw.

Metal Valve (Clamp-In) style TPMS Sensors have higher speed ratings (typically up to 155 mph) than Rubber Valve (Snap-In) styles (typically up to 115 mph).

Metal (Clamp-In) Installation: The valve piece is attached to the sensor body, and the valve core is secured with a nut and rubber grommet.

Program vs. Clone vs. Relearn Don't confuse TPMS Sensor Relearning, Programming and Cloning! Some processes require a Tire Pressure Monitoring System (TPMS) Programming Tool to complete, but not all processes are required (or available) for every application.

| PROGRAM |

Required only for Universal (Programmable) Sensors, in addition to TPMS Sensor Relearning. A TPMS Tool is required to:

- Program the specific Year/Make/Model protocol for the vehicle into the sensor

- Create or Clone a sensor ID onto the sensor

BEFORE INSTALLATION |

| CLONE |

Ideal for drivers who frequently swap wheels/tires, such as during the winter season. A relearn procedure is not required when sensors are cloned. A TPMS Tool is required to:

- Copy/Clone the unique ID from the original TPMS Sensor to the replacement sensor

BEFORE INSTALLATION |

| RELEARN |

Required when a new (not cloned) sensor ID is introduced or when the tires are rotated. A TPMS Tool may be required to:

- Write the unique sensor IDs to the vehicle's computer

- Assign the IDs to the correct wheel position (for vehicles that display pressure by location)

AFTER INSTALLATION |

|

| OEM / Interchange Numbers: QS101R, QS102R, QS103R, QS104R, QS105R |

|