|

GPD 13339C

|

|

$238.79

Price

|

$0.00

Core

|

+ Sold in packs of 1x1

Pack

|

$238.79

Total

|

|

|

(Only 1 Remaining)

|

|

|

| GPD 13339C Specifications |

|---|

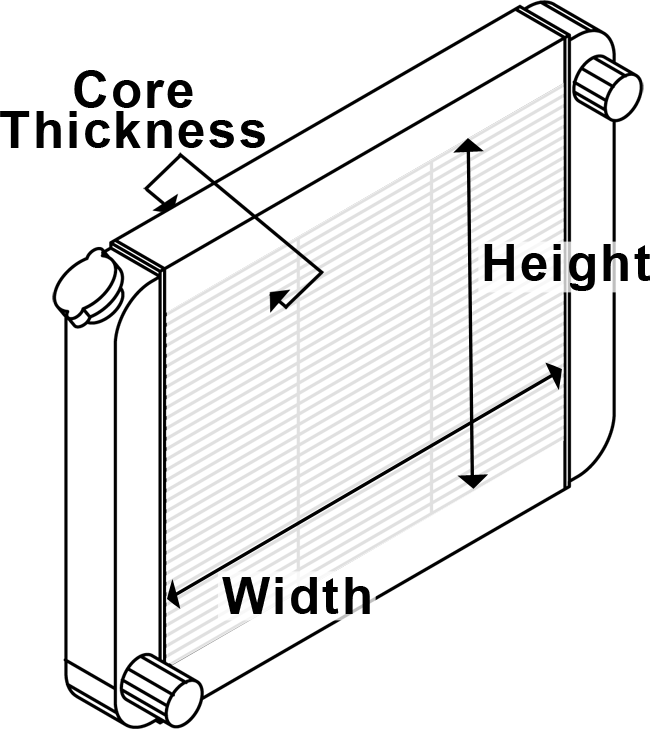

| Core Fin Quantity | 78 (every 4") | | Core Height | 20.51 IN | | Core Material | Aluminum | | Core Thickness | 1.65 IN | | Core Width | 39.29 IN | | Down Flow Or Cross Flow Type | Cross Flow | | Engine Oil Cooler Included | No | | Inlet Diameter | 1.02 IN | | Tank Material | Plastic | | Transmission Oil Cooler Included | No |

|

|

Most engines with a turbocharger or supercharger should use an Intercooler

to make the forced induction system more efficient. Intercoolers increase the density (oxygen content) of the air supplied to the engine by cooling the air compressed by the turbocharger or supercharger. By reducing the temperature and pushing more oxygen-rich air to the engine, more fuel can be burned to improve combustion and give the engine more power. Air-to-Air Intercoolers extract heat from compressed air through a network of tubes with cooling fins. Cool high-flow air from the outside absorbs heat from the cooling fins to

reduce the temperature of the compressed air passing to the engine.

All GPD Intercoolers are:

- Leak tested

- Designed to meet or exceed OE fit, form and function

- Durability tested on every new design

Service Tip: If you are experiencing unexplained or reoccurring radiator core leaks, or notice dark spots on your failed radiator core, test your coolant for Electrolysis. If detected, correct the source of the problem before replacing your failed radiator to prevent repeat failure.

gpd's Testing Process

As part of the new product development process, gpd radiators undergo the following tests to ensure durability and performance:

- Thermal Cycle Test

- Heat & Cool Cycle Test for 33,000 cycles

- Corrosion Test

- Wind Tunnel & Performance Test against OE sample

Measurement Guide

Cooling System Maintenance | Tips & Tools Without regular maintenance, cooling system components will degrade and fail prematurely, which can lead to costly engine damage. Protect your engine with simple preventative maintenance:

- Completely drain and flush the system using Cooling System Flush prior to installation. Flushing the system is critical to prevent system contamination and failure.

- Consider replacing the Radiator Hoses (and Hose Clamps), Thermostat and Radiator Cap as part of routine preventative maintenance. System contamination can cause these parts to degrade and fail over time, which can lead to severe engine damage from overheating.

- Refill radiator with fresh Coolant / Antifreeze according to the volume and formula specified in your Owner's Manual. Inspect levels and condition every year.

Additional Resources

Electrolysis in Heat Exchange Products

Radiator Installation Guide

Radiators with Engine and Transmission Oil Coolers

|

| OEM / Interchange Numbers: BC3Z8005D, BC3Z8005L |

Warranty Information:12 Months |

|